Extensive SMA Experience

At AMTI we offer both capability and our experience. Our SMA specialists have years of familiarity in developing and

executing bold SMA solutions for a wide array of clients.

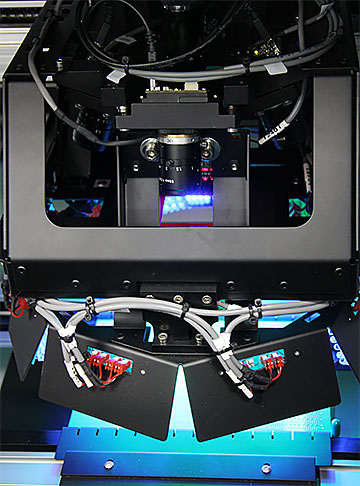

Diagnostics and Inspection

Use of X-ray and Auto Optical Inspection equipment ensures processes are secure and your results are perfect. This capability allows AMTI to detect issues faster and ultimately produce higher yields.

One Source - One Partner

AMTI offers a wide range of complimenting service capabilities (performed in-house) such as potting and conformal coating to support through-hole assemblies.

In-House Design Engineering

AMTI has an in-house design engineering team that is closely integrated with our production teams. This allows for a seamless transition from prototyping to NPI production and saves expenses.

Complex Components

Our process and manufacturing teams have the tools, talent and experience to implement solutions using cutting edge

components. (BGA, MicroBGA, QFN, QFP, LGA, MLP, Flip Chip, Package on Package)

Cost Savings Potential

Our team can examine your product and identify opportunities and potential risks for your design team to evaluate. Our efforts are geared towards improving product quality and lowering production costs.

Data / Quality System

A fully vetted and detailed quality data collection and analysis system is tied into all test processes. Providing real-time data and rapid response to excessive failures.

Materials & Process

AMTI uses proven potting and conformal coating chemical products backed by assembly preparation and decontamination

processes to ensure proper application.

In-House Training

AMTI has two full time IPC trainers on-staff. All hand solder operators are IPC 610 certified and our IPC trainers contribute to the final inspection of the product.

Quality & Process Control

Ruggedized products demand tight process control and a strong quality system. AMTI is ISO 9001:2015 certified and

AS-9100 compliant.

Standards Compliance

AMTI is an ISO 9001:2015 registered company that operates and deemed by certifying 3rd parties as compliant with

AS-9100 and TS-16949 Quality Standards.

It's in the Process Core

Almost all processes were designed from the beginning to support serialization and lot coding. This makes your

requirement not an exception, but rather, the rule.